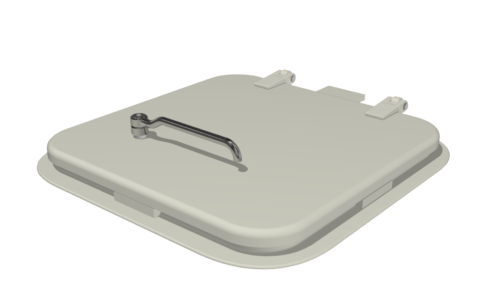

Hatches Hand Operated

Watertight Hatches, Angle bar Coaming

- Always checked and tested for the required water pressure

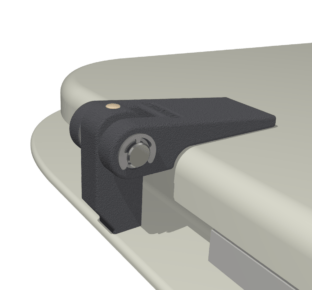

- Hatches are also equipped with our well-known Winel Musketeer closing mechanism

About this product

General information

Watertight hatches are required in watertight compartments. Winel watertight hatches are always checked and tested for the water pressure indicated by the class and customer and are supplied as a completely finished and tested hatch, ready to be welded in. The design and manufacture of our hatches are in full compliance with class regulations regarding watertight hatches and can be individually approved by all major classification societies. Which rules and regulations are applicable depends on the type of vessel, classification society and the position on the ship. This is of course based on the assumption that the approved door & hatch plan covers the approval to place this door in that specific position.

- Min. Width

- 550mm

- Min. Height

- 550mm

- Doorblades

- 8 mm blades

- Closing Points

- 3.40 metres

- Frame

- Aluminium, steel, stainless steel

- Open Close Indication

- Yes

- Including

- Open, Close indication

- Water Pressure

- Tested up to 12 mwc

- Insulation

- A60

|

|

|

|

|

|

|

|

|

|

|

|

Product features

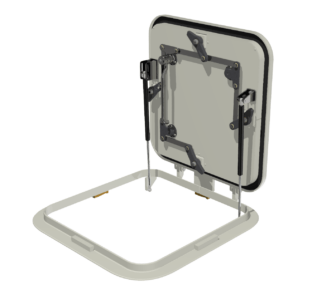

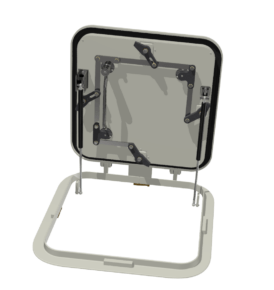

Winel hatches with angle bar frame can be executed in two base models:

- No opening support

- Gas spring

Construction:

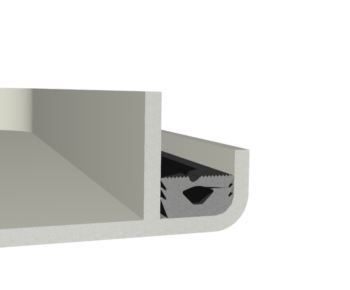

- Coaming thickness standard 7 mm (L 75x50x7), rounded edge to prevent damage to seal

- Adjustable hinges (2x), can be adjusted with standard tools, identical to doors

- Inside Radius of clear opening : R =100mm

- Hatch plate 8 mm (class approved)

- Adequate stiffening of hatch cover for watertight-or weathertightness if required

- Seal: 42×20 mm EPDM 30 shore

- Closing system: Winel musketeer system

The hinge points have a fixed turning point. In case of a rectangular clear opening, the hinge side needs to be specified.

- Steel

- Stainless steel

- Aluminium

- Open-closed indication

- Insulation

- Hasp & Eye

- Handgrip